Reinforced and pre-stressed concrete, like steel, do not burn; they are Class A materials. They also have low thermal conductivity that brings some degree of fire resistance. Apparently, there is no need to upgrade concrete fire resistance.

So, why does a concrete structure collapses in a fire?

Because the natural fire resistance of concrete is usually not enough.

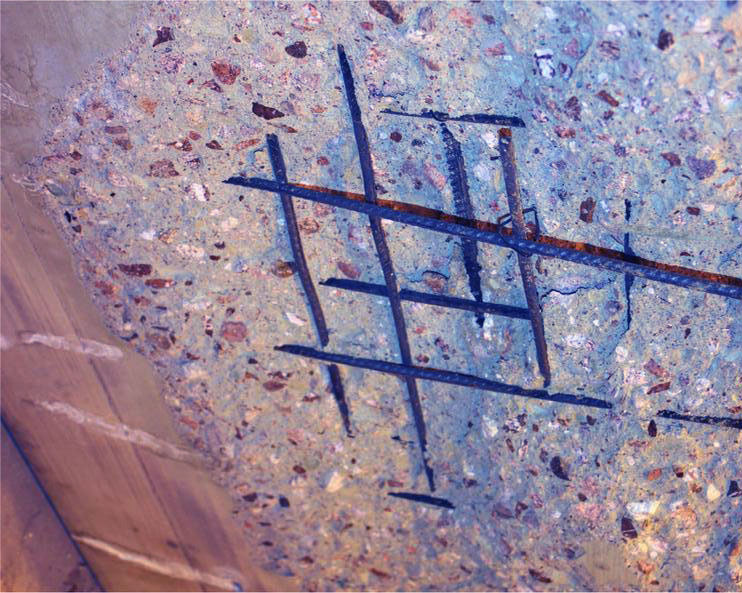

The high temperature generated by fire progressively penetrates inside the concrete, reaching the reinforcing bars. When these bars hit their critical temperature, the structure collapses.

This process hastens with spalling, which is the breakdown of the concrete surface that dramatically reduces the concrete cover, exposing the reinforcing bars to flames.

In most cases, concrete buildings made in recent decades do not require any additional fire protection because the existing concrete cover offers enough insulation to keep rebars below critical temperature all along the time requested.

Nonetheless, most of concrete buildings built until the eighties need a fire resistance upgrade.

The remedy lies in the application of protective materials, such as lightweight cementitious mortar, fire boards, or the avant-garde AITHON A90H.

Lightweight cementicious products have origin in the dense concrete that was often used to fireproof industrial facilities and encase steel beams up until around the mid-twentieth century.

Lightweight cementitious plasters progressively replaced dense concrete, that was cheap and resistant, but not easy to apply. Today cementitious coatings remain relatively inexpensive materials for the fireproofing of facilities. Though labor does have the potential to drive up the cost of these jobs because they must be applied in several, slow successive coats, they are still suited for dry environments where the substrate with minimal vibrations.

Furthermore,, cementicious products are not aesthetically pleasing, and often requite the addition of a suspended ceiling.

Fire protection boards, a traditional choice, prove reliable and are easy to apply on large flat surfaces; but they pose challenges when retrofitting existing concrete building, where a network of technical plants is usually present.

Removing all plants to allow fireboard application is a complex, time consuming and expensive work.

The installation around beams can be complex too, making this solution generally the most expensive.

Our solution

AITHON A90H has been developed to address the drawback of traditional methods. Adopted across more than 25 countries ranging from U.K. to Australia, it transcends mere fire protection, offering comprehensive refurbishment services.

Fire engineering design for concrete structures consists of an assessment of the thermal exposure, an estimation of the temperature distribution within the member and an assessment of the resistance of the member subject to the design fire exposure.

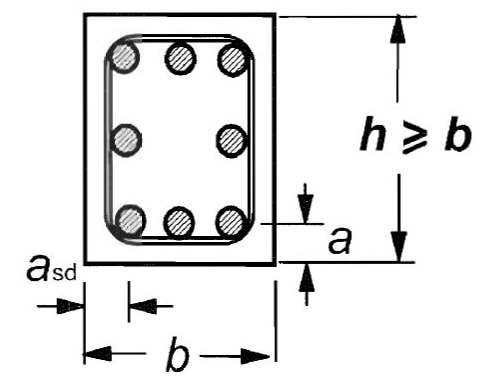

To ensure that the temperature of steel reinforcements never reaches the critical temperature, the minimum nominal axis distance (NAD) is required.

The nominal axis distance is the sum of the concrete cover to rebar and the rebar radius (a in the image). Eurocode 2 (BS EN 1992-1-2) specifies the calculation method of the minimum NAD. This minimum value of nominal axis distance determines the fire safety design for concrete members for a given standard fire resistance period.

The first problem in all refurbishment projects is defining the starting point, which means calculating in detail the existing fire resistance of the concrete structures, and verifying the reliability of the concrete substrate that has to support the fire protection system.

That’s why our approach consists of providing:

- Concrete repair specifications

- Adhesion/cohesion testing between rendering, plastering mortars or old paints and the substrate to which they are applied, to verify that they are a suitable substrate for a fire protection coating.

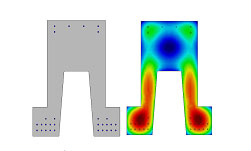

Pull-off or other type of tests are performed, according to the substrate. - Detailed cover survey based on thermal map modelling, for a precise evaluation of the existing level of fire resistance and the exact calculation of the quantities of AITHON A90H required for the fire resistance upgrade.

- Trained personnel approved by AITHON handle the application, ensuring compliance and thickness verification through third-party certification.

- The service extends to the issuance of a Fire Resistance Structural Appraisal according to the BS EN 1992-1-2.

These services are provided by IDF, an independent fire engineering company with global expertise, particularly in the field of reinforced concrete.